-

Products𐃬

As the global energy transition enters the "fast lane," with the sustained boom in the new energy vehicle and energy storage markets, the lithium battery industry is ushering in a new growth cycle characterized by "high-end, large-scale, and intelligent" development. Faced with the dual pressures of ramping up production capacity and implementing strict quality control, the intelligent upgrade of the slurry mixing process has become a key link for lithium battery enterprises to build core manufacturing advantages.

To address the common challenges faced by the industry, EVOC brought its Lithium Battery Slurry Mixer Solution to the production line of a well-known lithium battery manufacturer, initiating an intelligent transformation of the slurry mixing process. This case reveals how the key equipment, the IPC-310, systematically breaks through production bottlenecks within the intelligent solution, achieving a dual enhancement in both quality and efficiency.

Challenge One: Insufficient Dosing Accuracy and Challenges in Ensuring Batch Consistency

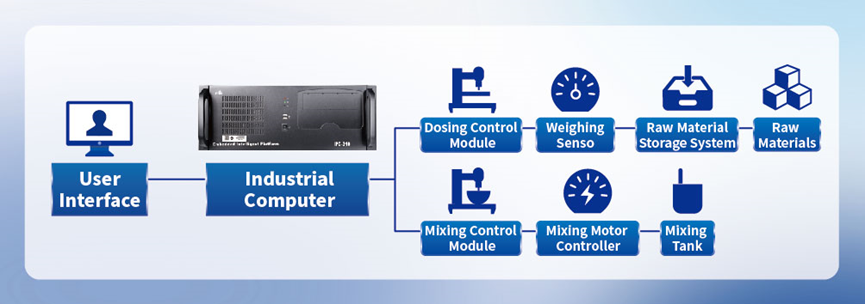

Intelligent Solution: The EVOC IPC-310 connects to the dosing control module and high-precision weighing sensors, enabling highly accurate ingredient feeding and ensuring slurry uniformity. Simultaneously, the entire process data is automatically recorded and stored, forming a traceable "digital formula" that ensures the composition of each slurry batch is verifiable.

Customer Testimonial:The IPC-310 delivers a win-win for both quality control and cost management. It not only helps us improve dosing consistency and reduce raw material waste but, more importantly, now every batch of slurry comes with a complete "data file."

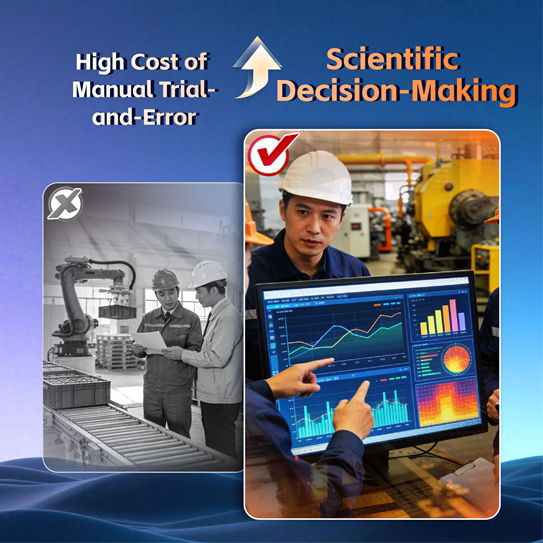

Challenge Two: Reliance on Experience for Process Optimization, Lack of Data Support

Data-Driven Approach: By establishing an integrated data platform that monitors key indicators in real-time—such as temperature, pressure, and mixing status during the slurry mixing process—the built-in data analytics engine provides real-time feedback and s. This offers clear data support and scientific recommendations for optimizing process parameters.

Customer Testimonial:With the data platform in place, we now have a clear understanding of which parameters to optimize and how to adjust them. It not only frees personnel from operational risks but also saves substantial trial-and-error costs, translating into real financial savings.

Challenge Three: Independent Component Control Leading to Low Maintenance Efficiency

Unified Platform: The core of the EVOC Lithium Battery Slurry Mixer Solution lies in building a highly integrated unified control platform. Status monitoring for all subsystems, system parameter settings, fault diagnosis, and data analysis can all be performed through the IPC-310 industrial computer interface, significantly simplifying operational procedures.

Customer Testimonial: In the past, it took us 2-3 hours on average to troubleshoot a fault, which was very inefficient. Now, with diagnostics through the unified platform, we can quickly pinpoint the core issue. Our daily routine has also shifted from "patrol inspections" to "monitoring the screen" reducing the workload by half.

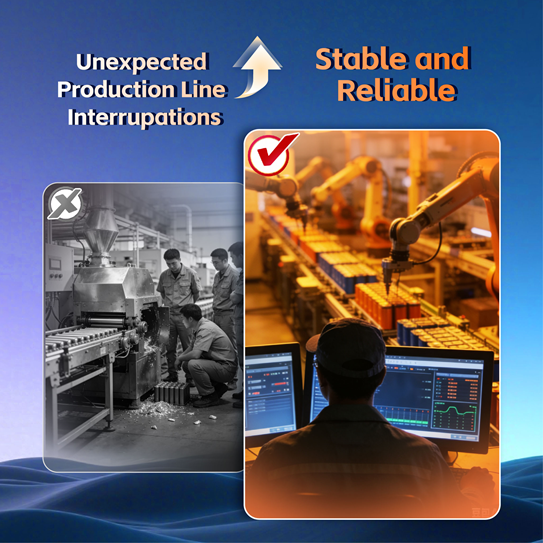

Challenge Four: Poor System Stability, Frequent Production Interruptions

Stable Support: The EVOC IPC-310 industrial computer is built on an industrial-grade hardware platform with reinforced design, offering excellent features such as dust resistance, wide-temperature tolerance, and anti-interference capabilities. Its integrated real-time operating system (RTOS) lays a solid foundation for the continuous, stable, and reliable operation of the entire slurry mixing process.

Customer Testimonial:Since upgrading to the new equipment, we've felt significantly more at ease. We no longer have to worry anxiously about emergency equipment repairs.

In today's increasingly fierce competition over lithium battery performance, the EVOC Lithium Battery Slurry Mixer Solution, with the IPC-310 at its core, establishes a stable and efficient digital-intelligent production foundation for enterprises through a synergistic system of precise execution, data-driven operations, unified control, and reliable performance.